Our Services

CAD Onsite Services

We will send highly qualified CAD designers to your site to make a concept in your thoughts into a 3D CAD model on your computer. We will analyze the model through various checks and reviews. We will work with your engineers from the conceptual stage until it becomes the final 3D CAD model. We will keep updating the model until the model is perfectly ready for the real-world part. We can also work with actual drawings such as automotive part drawings, electrical drawings, architectural drawings, aerospace drawings, and any drawings you have. When you need any work on a 3D CAD file, we can do it fast and at a very low cost.

CAD conversion

Do you have CAD models and drawings from suppliers and convert them into your company CAD software for future change? Do you need to save them in your PLM system? We can definitely help you in doing any CAD conversion work or any temporary CAD work you have and upload all the files to your system.

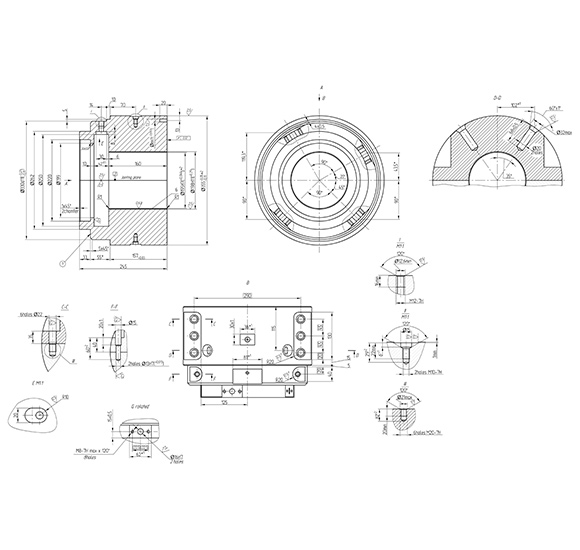

2D Drawing

GD&T check

Tolerance stack-up

Assembly sequence for manufacturing

As you know, 2D drawings are legally binding document that are used for quotations and a communication tool among engineering, manufacturing, and quality control. Inaccurate presentation on drawings leads to quotation change, make bad parts accepted or throw away good parts.

To minimize these problems, CAD CAT has various review stages. GD&T specialist makes sure the drawings are completed with correct design rules and interpolation is done correctly. A stack-up tolerance calculation engineer determines critical dimensions and tolerances to make sure there is no mistakes on assembly. These two verification steps that we provide are important to save overall time and cost. We can also support manufacturing sequence document so that you can see how to assemble all the parts together in manufacturing line. From this assembly process sequence, we help engineers to modify design to be optimized to meet manufacturing requirements.

DIMENSIONAL CHECK WITH NON-FUNCTIONAL PARTS

Do you need to check your design dimensions to make sure all dimensions are correct before your expensive long lead time tooling? We are here to help you with this. We can build your mockup assembly by using non-functional parts such as 3D printing, CNC machined parts, and prototype wires and components to ensure that the design is good and manufacturable while the design is in progress or even after the design is finished. Based on CAD design, we can build these non-functional components and assemble them together in your company so that we can all see how all the parts fit together and if there is an issue with assembly. Most of all, assembly sequence can be thought in this stage more clearly in this validation step before you finalize tooling. This verification process can save a significant amount of time and money because you can find design issues that you did not think of before manufacturing.

Why Choose Us

We have highly qualified staffs for our services. We will make your concept to CAD design with your timeline.